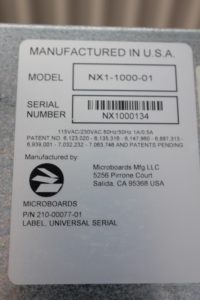

I have been building an automated CD ripping machine for a while now, and during the research phase I stumbled upon some commercial solutions developed by Microboards Technology. The older designs are made by Champion Duplicators Inc. which Microboards acquired in 2000.

The loading mechanism used in these devices seems quite novel, so I decided to buy one on eBay for further studies. I could possibly use some of the parts in my own design as well – I have first-hand experience in how tricky mechanisms are to get to work right.

These units weigh about 12 – 15 kg – therefore the shipping from USA was not cheap! The dimensions are 388 x 254 x 241 mm. While the volume may seem big, it does contain three optical drives which take a lot of room.

The loader mechanism is based on a big servo which pushes a spring-loaded metal sheet. Basically the metal sheet has a circular opening, which gets aligned with another hole when the servo moves it. The other hole is not perfectly round but has some flanges on the sides, ensuring that only one CD gets loaded per stroke.

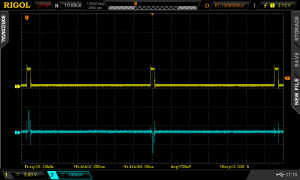

Underneath there is a spindle which moves up and down on a rail. This moves the CD vertically. The trays of the DVD drives have slots cut in them so that the arm of the spindle can move even when the tray is open. The red and black wires on the left belong to the limit switches of the spindle arm carriage.

When the CDs have been processed, they go to a conveyor made of polyurethane belt. As the unit is quite old (some parts have a manufacturing date of 2006, others 2009 and 2010) the belts have already gone bad. When the unit was powered on, it would not pass the self-test because the belt of the spindle arm was slipping.

The unit has three IDE drives, two of which can record. The third one can be used to read the master disc which the two other drives write. Obviously using two drives instead of one is faster.

The unit also has a hard drive. According to the manual it can be used for ripping audio CDs.

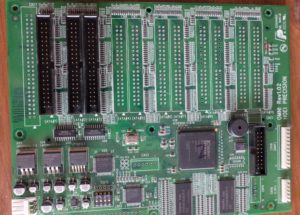

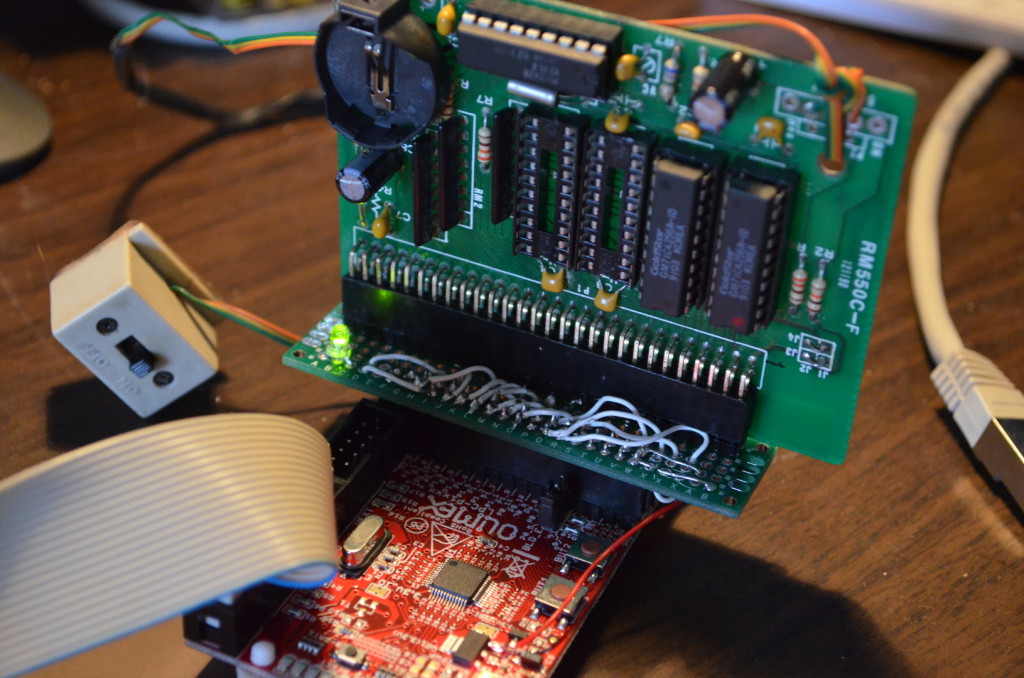

There are two controller boards. One of the boards sits on top of the whole unit, and is used for interfacing to motors and limit switches.

The main board is buried under the optical drives. It boasts a handful of CPLDs and an FPGA.

The entire thing is powered by a beefy APS power supply.

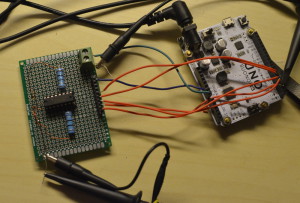

As I have no use for a device which makes a zillion copies of a CD I am planning to use some of the parts of this unit to create my own ripping station. The brains will get replaced by a modern single-board computer and I will reduce the number of drives to just one. I am also trying to get the volume and the power consumption of the device down.